Design & Simulation

Route modeling, power budgeting, thermal modeling, grid interconnect sizing.

Electrovia enables all EVs — including heavy-duty trucks — to charge dynamically at highway speeds and during stops, reducing downtime and allowing for smaller, more efficient battery packs. With full corridor implementation, vehicles can finish their routes with the same state of charge they had when they started.

From concept to energized corridor — we deliver end-to-end wireless charging infrastructure.

Route modeling, power budgeting, thermal modeling, grid interconnect sizing.

Precast roadway panels and high-power electronics built for serviceability.

Install, commission, operate — controls, telemetry, and safety monitoring.

Open market wireless energy sales operations to users travelling along booster enabled routes.

A building-block platform for in-motion and static opportunity charging.

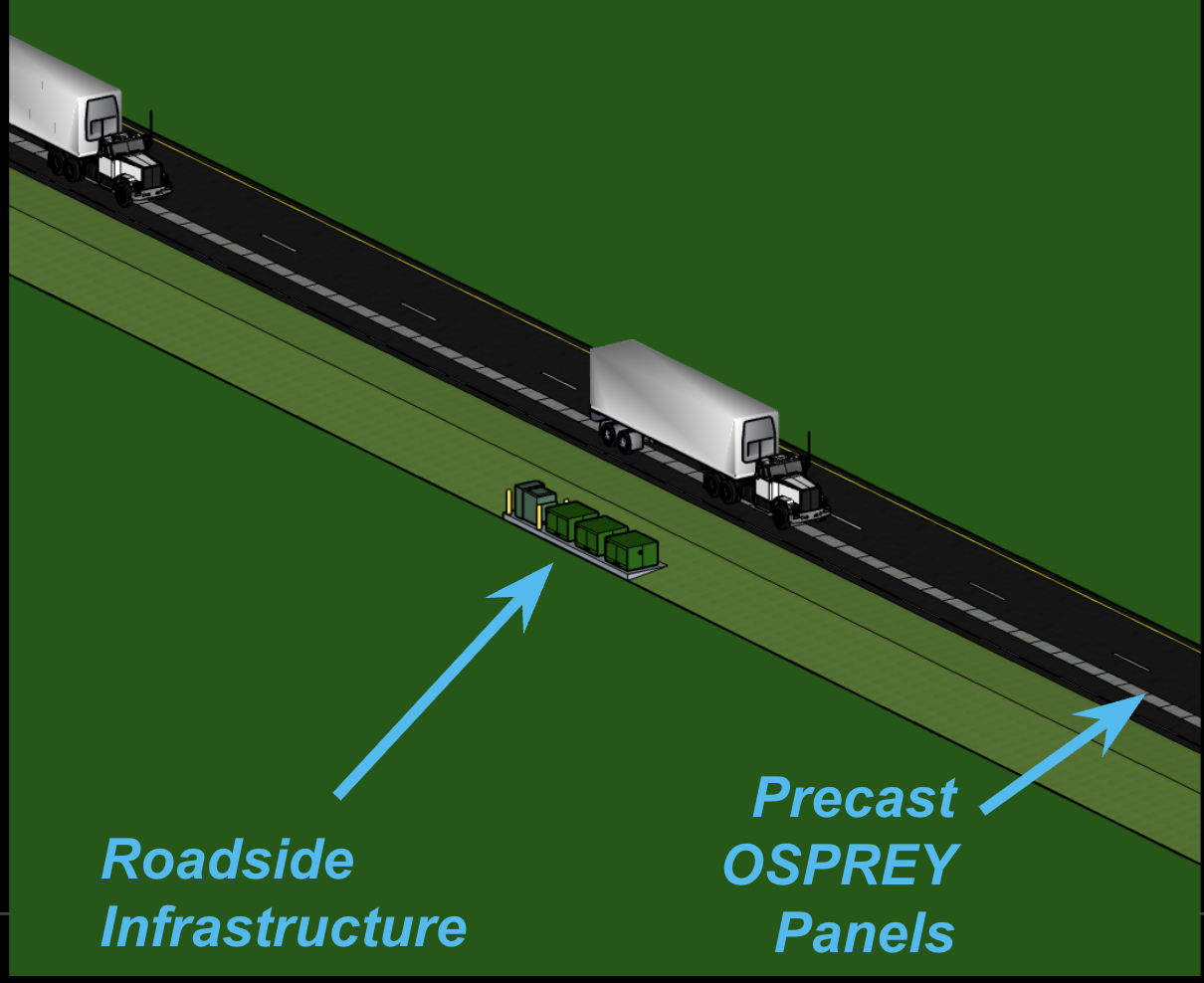

Modular precast concrete panels functioning as the wireless power transmitter, roadway surface, and conduit for corridor power sharing.

Containerized power distribution infrastructure and optional utility-grade Battery Energy Storage System.

Vehicle-mounted receivers for high-efficiency transfer.

Electrovia's open protocol allowing any manufacturer to build receivers capable of wireless power transfer.

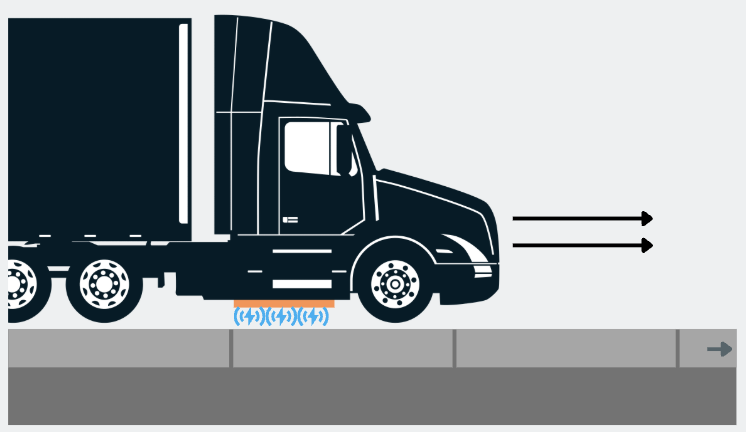

Electrovia's system uses inductive resonant coupling to create a combined magnetic field that induces current in a tuned onboard vehicle receiver.

Booster segments placed every ~10 miles energize as trucks pass, delivering up to 500 kW per receiver. THOR cabinets and BESS stabilize the DC bus; KITE receivers close the loop onboard.

By energizing short “booster” segments along a route, vehicles top up while moving. That means smaller batteries, less roadside hardware, smoother grid demand, and higher vehicle uptime.

Charge along the route instead of carrying all the energy onboard—reduces mass and cost, increases payload, and improves efficiency.

Distributed boosters replace oversized fast-charge hubs, cutting siting complexity and queuing areas.

Load is spread across miles of corridor and time, avoiding localized spikes and using under-utilized capacity.

Corridors pair with storage to shape demand, support renewables, and provide peak shaving where it matters most.

No detours or dwell time at chargers; fleets stay on schedule while keeping state-of-charge balanced.

Static Wireless Charging (SWC) uses the same OSPREY™ hardware and power electronics as our in-motion system. Start at predictable locations (depots, yards, docks) to build familiarity, then scale to dynamic corridors.

One standardized system for both in-motion and stationary use — simplifies deployment, maintenance, and scaling.

Begin with static charging at predictable locations to build operator familiarity and confidence.

Modular panels embedded at docks enable charging during normal load/unload cycles with minimal disruption.

Pair with BESS for peak shaving and grid services (e.g., load balancing, frequency/voltage support).

Have questions about our technology, partnerships, or just want to get in touch? We'd love to hear from you.